Plate Mounted Sickle Blade - Type Industrial

|

|

|

Features

- All fans include a one piece bell mouth mounting plate.

- The motor and fan impeller are supported within this mounting plate by a strong electro welded steel support frame.

- All models also include a steel finger proof guard, ISO 13582, as standard mounted to the inlet side of the fan as well as condensation drain holes.

- There are 8 standard sizes from 250 to 630mm, all fully speed controllable and can operate up to 95% humidity.

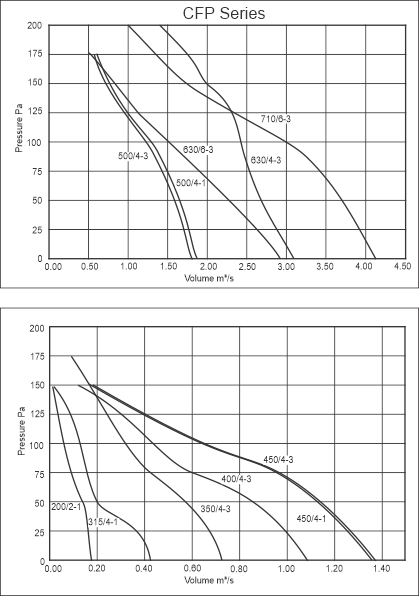

- The fans produce air volume flow rates of up to 4,2m3/s and can handle static pressure up to 200Pa.

|

|

Motors

- All CFP plate mounted Sickle Blade Axial fans incorporate asynchronous induction type motors with squirrel cage external rotors.

- Sealed for life ball bearings can be operated at any angle.

- The motors are protected to IP54 with Class F insulation, suitable for operating temperatures up to 55°C with thermal overload protection on the single phase.

- Two, four and six pole motors are available.

|

| |

|

| |

|

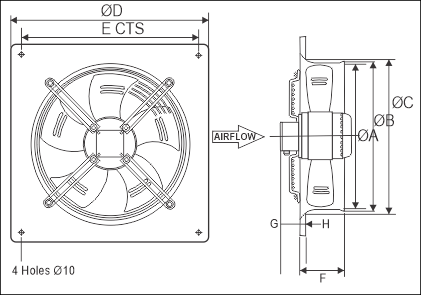

Dimensions

|

| Model |

Aø |

Bø |

Cø |

D |

E |

F |

G |

H |

Kg |

| 200 |

200 |

210 |

215 |

315 |

260 |

50 |

60 |

15 |

2 |

| 250 |

250 |

260 |

265 |

370 |

320 |

90 |

60 |

15 |

3 |

| 350 |

350 |

360 |

395 |

485 |

435 |

90 |

60 |

15 |

4.9 |

| 400 |

400 |

410 |

450 |

540 |

490 |

110 |

60 |

15 |

7.2 |

| 450 |

450 |

460 |

500 |

575 |

535 |

110 |

60 |

15 |

7.2 |

| 500 |

500 |

510 |

560 |

655 |

615 |

115 |

60 |

15 |

9.5 |

| 630 |

630 |

645 |

705 |

805 |

750 |

125 |

60 |

20 |

15 |

| 710 |

710 |

720 |

740 |

850 |

810 |

130 |

140 |

25 |

37.5 |

|

Technical Data

|

| |

m3/s @ Pa |

|

|

FLC |

SC |

Input |

dB(A)@ |

|

| Model |

0 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

V |

r/min |

Amps |

Amps |

Power W |

3m |

Kg |

| 200/2-1 |

0.175 |

0.162 |

0.142 |

0.095 |

0.062 |

0.032 |

0.014 |

|

|

240/1/150 |

2400 |

0.26 |

0.8 |

60 |

41 |

2.5 |

| 250/2-1 |

0.354 |

0.326 |

0.258 |

0.168 |

0.142 |

1.121 |

0.101 |

0.081 |

0.056 |

240/1/150 |

2600 |

0.4 |

1.2 |

90 |

51 |

3 |

| 350/4-1 |

0.726 |

0.672 |

0.582 |

0.437 |

0.322 |

1.240 |

0.169 |

0.096 |

|

240/1/150 |

2500 |

0.7 |

2.1 |

150 |

53 |

4.9 |

| 350/4-3 |

0.716 |

0.662 |

0.574 |

0.431 |

0.317 |

0.237 |

0.167 |

0.095 |

|

400/3/50 |

1380 |

0.38 |

1.1 |

140 |

53 |

4.9 |

| 400/4-1 |

1.083 |

0.983 |

0.874 |

0.613 |

0.435 |

0.311 |

0.124 |

|

|

240/1/150 |

1380 |

0.82 |

2.5 |

180 |

59 |

7.2 |

| 400/4-3 |

1.083 |

0.983 |

0.874 |

0.613 |

0.435 |

0.311 |

0.124 |

|

|

400/3/150 |

1380 |

0.47 |

1.6 |

180 |

59 |

7.2 |

| 450/4-1 |

1.365 |

1.245 |

1.134 |

0.971 |

0.641 |

0.417 |

0.182 |

|

|

240/1/150 |

1350 |

1.1 |

3.3 |

250 |

59 |

7.2 |

| 450/4-3 |

1.375 |

1.254 |

1.142 |

0.977 |

0.646 |

0.420 |

0.183 |

|

|

400/3/150 |

1360 |

0.6 |

1.84 |

250 |

59 |

72 |

| 500/4-1 |

1.871 |

1.767 |

1.648 |

1.497 |

1.278 |

0.979 |

0.761 |

0.588 |

|

240/1/150 |

1370 |

1.55 |

4.7 |

350 |

63 |

9.5 |

| 500/4-3 |

1.803 |

1.703 |

1.588 |

1.442 |

1.231 |

0.943 |

0.733 |

0.567 |

|

400/3/150 |

1320 |

0.9 |

2.65 |

350 |

61 |

9.5 |

| 630/4-3 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

|

|

400/3/150 |

1370 |

1.45 |

2.8 |

770 |

78 |

15 |

| 630/6-3 |

2.916 |

2.916 |

2.651 |

2.342 |

1.949 |

1.140 |

0.828 |

0.530 |

|

400/3/150 |

900 |

1.56 |

4.7 |

600 |

66 |

15 |

| 710/68-3 |

4.130 |

3.929 |

3.693 |

3.400 |

3.001 |

2.399 |

1.768 |

1.342 |

|

400/3/150 |

900 |

1.75 |

5.3 |

900 |

71 |

37.5 |

|

| |

|

|

|